Automation Blog

E-Actuators Safely Control Renewable Energy Turbine Motion

As the world continues to transition from traditional, fossil fuel-based forms of energy to clean, renewable energy sources, hydro and wind power are at the forefront of this shift. While they offer society clear benefits such as low greenhouse gas emissions, the turbines that harness hydro and wind power require accurate, controllable motion. Whether used for fluid control in Pelton turbines or regulating pitch in eolic applications, electric- or E-actuators are an effective means of ensuring turbine systems perform at their best.

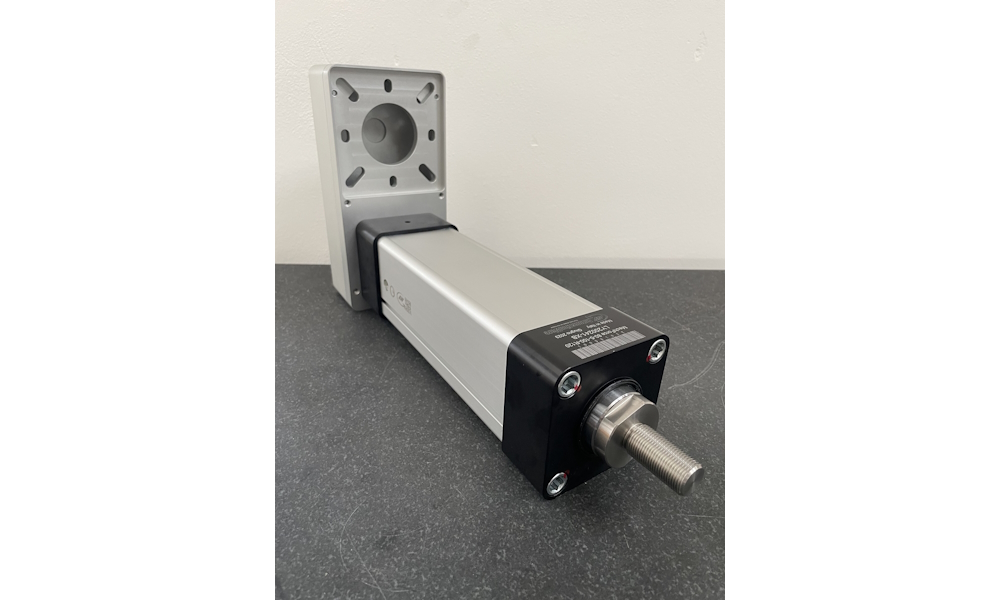

Here’s an overview of how electric actuators work in turbine systems, using Automationware’s Mech Force Series actuators as an example.

Hydroelectric power. Pelton wheels rely on a stream of high-pressure water from a penstock pipe to create the rotation that converts the water jet’s kinetic energy into mechanical power. Water flow must be regulated in order to respond to fluctuating power demands or river flow changes while also ensuring the wheel turns at its intended rotations per minute (rpm). E-actuators move a spear situated inside the nozzle that opens and closes the water jet inlet to achieve the desired flow rate.

Our E-actuators are well-suited for this application thanks to a ball screw transmission system that enables high-speed operation and high thrust performance. They also feature custom sphere recirculation screws to allow high dynamic load handling and exceptional speed performance. Integrated encoders within the drive system ensure accurate movement.

Eolic applications. Pitch systems adjust the angle of a wind turbine’s blades to optimize the available wind energy without exceeding their rated values. They act as a fail-safe break that slows or halts blade rotation should a breakdown occur. Because actuators are crucial to both the efficiency and safety of a turbine, they must be durable, reliable and safe.

Not only are our Mech Force E-actuators ideal for energy applications, such as Pelton wheels and wind turbine pitch systems, we can also customize our standard versions to ensure safety and reliability. Mech Force E-actuators are available with a specially designed ball screw transmission system that includes an integrated spring and elastomer coupling. Together, the assembly closes the system when the motor is unable to control the system. This added redundancy offers greater safety for the entire turbine.

Optional AwareVu™ technology minimizes the effects of vibrations and provides advance warnings about any maintenance needs. Electric actuators feature a durable, reinforced structure and also offer additional benefits versus pneumatic actuators such as:

- Reduced fire risk. Hydraulic actuators may contain flammable oils.

- Energy savings. As part of servo systems, E-actuators typically consume less energy, depending on the installation.

- Reduced contamination risk. Hydraulic fluids and oils can potentially contaminate water or the surrounding environment. These fluids must also be replaced, sometimes in hard-to-reach locations.

- Easy installation. E-actuators are compact and require few connections.

Clean, Effective Motion Without Worries

To get the most from renewable energy sources, motion systems must be well-controlled, clean, reliable and safe. E-actuators, such as our durable Mech Force Series, deliver the precision and efficiency of electronic control without contaminants, fire risk and other worries.

IKO is the U.S. distribution partner for AutomationWare. You can download our brochure on Mech Series E-actuators at www.automationwareusa.com, or contact IKO at ikoaw_usa@ikonet.co.jp for more information.