Automation Blog

Cobots and Grippers Let Integrators Quickly Adapt To Changing Automated Processes

If you plan to use cobots for your high-end, precision manufacturing application, you’re probably factoring their long list of advantages into your decision. After all, cobots are known for their modularity, flexibility, ease of implementation, light weight and cost savings versus traditional industrial robots. And, with the right electronic gripper, or end effector, you can take these benefits even further. In fact, many electronic grippers are plug-and-play compatible with popular cobot brands.

Let’s take a look at how a cobot and electronic gripper work in tandem to provide greater flexibility, adaptability and productivity for your automated processes.

Start With a Modular Cobot

The AW-Tube cobot is appropriate for a wide range of applications and can be configured for different payloads and work areas. This flexibility is especially attractive for integrators looking to incorporate a cobot in multiple processes. You can even combine these modular and scalable units with existing mechatronics to satisfy both present and future application needs.

AW-Tube leverages the Robot Operating System (ROS) software environment to manage a complete work cell without the physical limitations created by control cabinets or proprietary kinematics inherent in other industrial robots. It also supports EtherCAT fieldbus for fast configuration and effective kinematic control.

Automationware electric grippers support most currently available cobots in high-performance applications such as electronics handling and semiconductor fabrication, precision assembly, packaging and laboratory automation. Designed with modular cobotics in mind, many of our grippers come with built-in drive controllers and communications electronics, allowing for easy setup, fast programming and implementation. They are also available in a wide range of clamping forces and strokes to satisfy various cobot deployments.

Additional features include:

- Precise force control.

- Short opening/closing times.

- IP67 protection.

- Long lifetime with minimal maintenance.

An Effective Combination

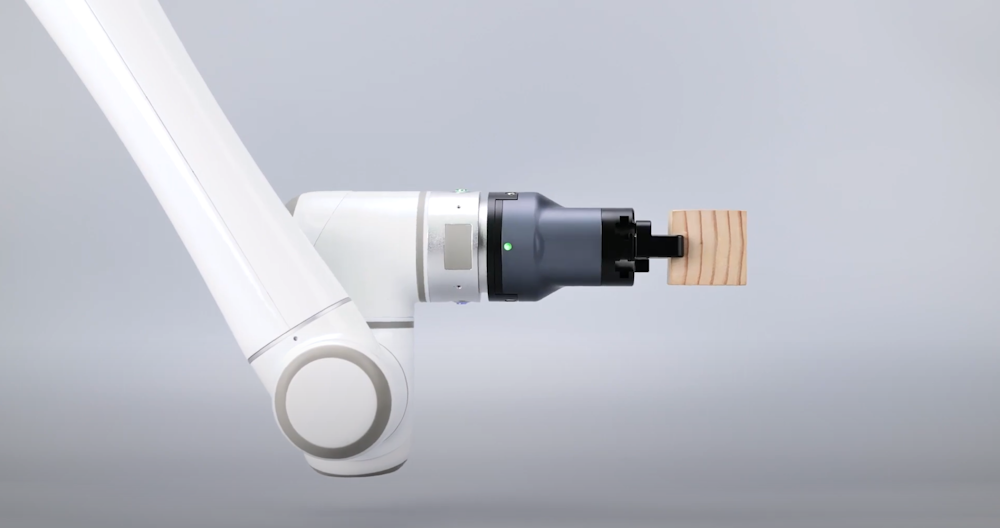

This video shows our AW-Tube in action while outfitted with a PGC40 electric parallel gripper. The PGC electric gripper family provides effective force control to deliver exceptional precision and high load handling for cobots, as well as heavy-duty applications. Depending on the size, the series offers gripping forces up to 300 N to handle payloads up to 6 kilograms (13.2 pounds) with ± 0.03-millimeter (0.001-inch) accuracy and come in stroke lengths from 37 to 60 millimeters (1.46 to 2.36 inches). It also offers adjustable gripping force for hard and soft loads, plus customizable fingertips to suit a variety of needs and a self-locking mechanism to maintain the grip when power is off.

Taken together, the AW-Tube and AW gripper combination delivers exceptional cobot modularity and flexibility for easy adaptation and redeployment when automated processes and work cells change. That means faster transitions with less system downtime and more productivity, resulting in greater returns for your robotics investment.

IKO is the U.S. distribution partner for AutomationWare. Visit www.automationwareusa.com, or contact IKO at ikoaw_usa@ikonet.co.jp for more information.